Our capabilities

We continue to focus on quality and customer service as we upgrade our capabilities and extend our capacities by acquiring more capable and efficient machinery and equipment. Our current capabilities include:

- Engineering & designing

- Tooling manufacturing

- Die casting

- Machining

- Metal stamping

- Welding

- Assembling

- Third-party testing service

To uphold our standards of excellence through every part of every job, we coordinate quality-approved outside services such as heat treating, electro plating, hot galvanizing, powder coating, anodizing, and painting for our customers.

We can provide a one stop solution to your needs. From design to tooling to production, we can do it all!

Engineering & Designing

Our people are what truly set us apart, strong Engineering and Development is the key to our success. Our team of engineering is a group of highly talented, energetic and service-oriented people with over 100 solid years of combined experience within our field. Some of our engineering capabilities include:

- Provide technical support to all aspects of our manufacturing processes.

- New product development and tooling design.

- Work with clients to meet specific requirements.

Our experts take pride in producing high quality work, having an excellent attention to detail, utilizing innovative designs, and being very responsive to our clients’ requests. Our innovative and flexible approach to design products, with a distinct willingness to think outside the box, allows us to provide clients with solutions that reduce project costs and increase property value, while meeting technical and regulatory requirements.

Tooling Manufacturing

Over 20 years in manufacturing, we have built a solid reputation in design and manufacture of complex mold and tooling for aluminum alloy die casting, metal stamping and machining.

With a quality design by our talented engineers as the foundation, in our fully equipped in-house mold making shop, our team of highly skilled toolmakers is able to build quality mold with the goal of decreasing costs and improving output.

Besides meeting with our own production needs, mold and tooling are part of our business nowadays

Die Casting

Our die casting process begins with your design. While in the design phase, we will partner with your engineering team to evaluate all tooling features and options which in-turn will help improve die life and minimize potential problems during the casting process. We can also work with you to produce the most cost-effective design by weighing the pros and cons to certain design features and trade-offs.

Using die casting machines capable of 180 to 900 tons locking force, combined with our creative engineering strength plus diversified production capabilities including experienced in-house tooling fabrication, whether it is as-cast or a complex assembly, aluminum or zinc alloy, we can provide customers with optimum die casting services that include shot blasting, complex machining, impregnation, tumbling, chromating, wet painting, powder coating, polishing, assembly and other finishing services.

Machining

We have been providing a full range of CNC machining services to a diverse range of industries for all of your business needs including drilling, boring, turning, threading, engineering and more. All of our machines utilize the up-to-date technology and are optimized to provide customers with the highest level of craftsmanship and quality at competitive prices.

We provide convenient machining to meet your specifications with responsive service from prototype to production. No project too big or too small for us, whether you’re looking for prototype machining or a giant batch order, our machining services have you covered.

Metal Stamping

Our business started form metal stamping. As a leading provider of metal stamping products, with over 30 different punch presses equipped to handle capacities from 35 tons to 250 tons, we now manufacture complex, high-quality parts and components for customers both domestically and internationally.

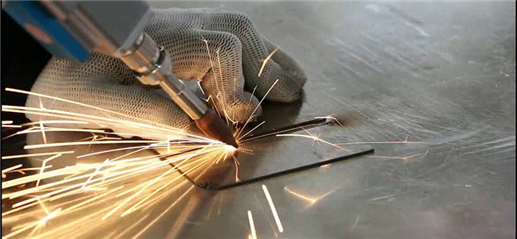

Welding

Right upon establishment of factory in 1998, we were providing a variety of welding services to complement our stamping and sheet metal fabrication operations for construction hardware.

Today, while continuing to play a major part in the steel and construction industries, from Spot Welding to MIG, TIG, and Stick Welding, our customers depend on our superior welding capabilities to fabricate their parts.

Assembling

We have been assembling metal parts for over 10 years. From raw materials to finished assemblies, from simple to the most complex, using manual as well as fully automated techniques, combining precision machining with complex assembly and other processes, we are able to build metal components and sub-assemblies, part of a part or a total part, kits and total assemblies for customers from various industries.

Third-party Testing Service

Besides assuring our own needs in production, our field and in-house laboratory also provides third-party testing service to those companies who are not able to test their products. Our testing service include:

- Tensile strength testing

- Chemical composition analysis

- Machenical property analysis

- Metalography examination

- Dimensions mesurement by CMM